EmlinQ Services | Material Management

The key fundamental goals of material management consist in the ability to minimize cash flow impact and ensure adequate and consistent supply of parts that will not adversely impact production and sales. This is accomplished in a number of ways, namely:

- In-plant (consignment) stores where parts are staged in our facilities based on customer orders/forecasts. We offer these solutions in both our Simi as well as our Mexicali facilities

- a robust internal supply chain process aided with the appropriate tools, including a modern ERP system for material planning

- tight inventory controls

- strong relationships and constant proactive communications with our suppliers both locally and internationally

We customize inventory management programs to fit individual customer needs and our purchasing staff will manage the supply chain to ensure the material remains on schedule.

In view of our AS9100 Rev D certification, traceability of parts is a critical component of our business. In view of this, all our parts can be traced to the manufacturer, and our policy is to deal with recognized and authorized distributors. Should there by any shortages or End-Of-Life situations which require us to approach brokers, a signed agreement from our customers would be required.

Related Services

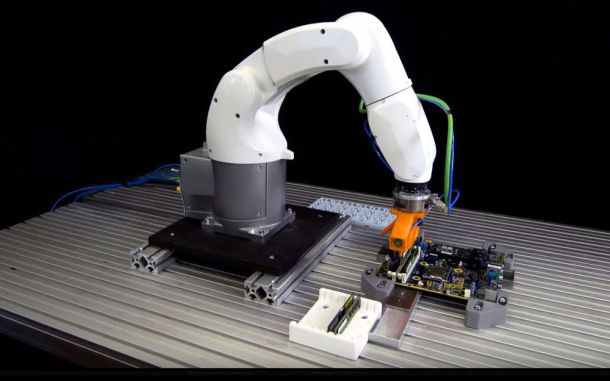

Prototype Builds

EMLinQ provides quick turn prototype manufacturing, including small quantity runs...

System Assembly

EMLinQ provides full turnkey PCB assembly, complete functional tests, burn-in, and final packaging...

Cable Assembly

EMLinQ, with a high volume KOMAX and Schlienberger machines, provides capabilities to address both...