Our materials.

Our environment.

EmlinQ Services | Inspection

EMLinQ is always loking for ways to build quality into our processes through Continuous Improvement and the implementation of our very own Zero Defect program. These efforts have afforded us to significantly reduce inspection times and costs to customers. With some of our partners, we carry out an annual Lean Management program to continuously make efforts to minimize waste and maximize efficiencies. This leads to better yields and lower costs.

We offer incoming, in-process, and final inspection processes performed by our trained staff and technicians. Our solderers are all trained to IPC-A-610D Class I, II, and III standard. Our state-of-the-art Automated Optical Inspection systems ensure manufacturing consistency by meeting international standards and requirements.

Visual Inspection is also carried out by a number of qualified and well trained inspectors.

Types of Inspection

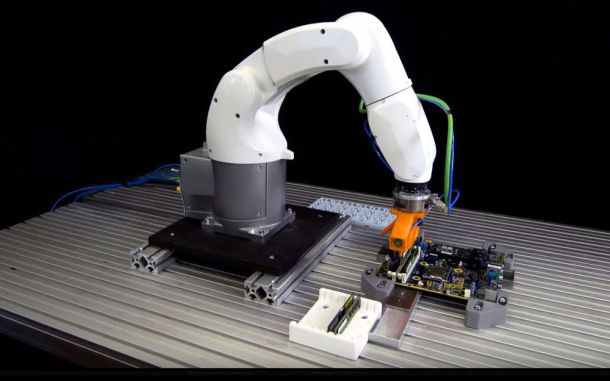

Automated Optical Inspection Systems (AOI)

- Ensures correct placement of all SMT components

- Precise and consistent automated solder inspection.

Electrical Verification of SMT component placements.

- Offered on all SMT placement machines

High Resolution X-Ray Inspection

- BGA Reflow Inspection

- X-Ray Rendering Inspection

- ESD Damage Detection

- Counterfeit Component Verification

OBA Audits - Every build goes through a final OBA process

Related Services

Prototype Builds

EMLinQ provides quick turn prototype manufacturing, including small quantity runs...

System Assembly

EMLinQ provides full turnkey PCB assembly, complete functional tests, burn-in, and final packaging...

Cable Assembly

EMLinQ, with a high volume KOMAX and Schlienberger machines, provides capabilities to address both...